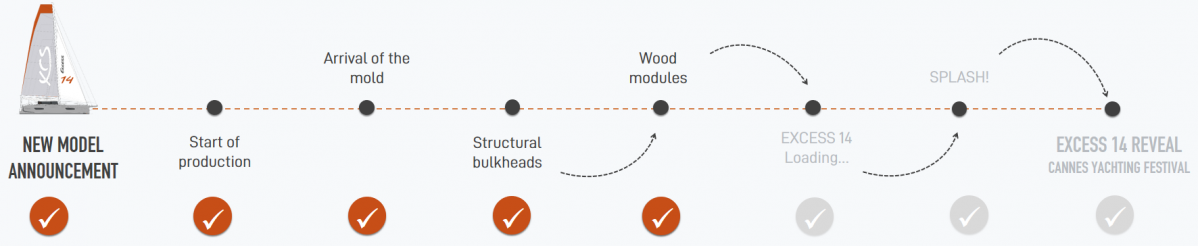

Excess 14 Series #3 The wood modules

As we have previously mentioned concerning the bulkheads, (see here), weight saving is a powerful lever to create a boat that offers more sensations.

This hunt for weight is systematically carried out throughout the Excess 14, but the design of the interior fittings, known in the industry jargon as ‘wood modules’, is a very good illustration of this.

Several design criteria will be typically considered by our woodworking designers:

- The functionality of the module: ergonomics, practicality, absence of interference in the movement of the doors, etc.

- The structure of the module, and how it integrates into the structure of the boat

- The design (respecting the aesthetics sought by the designer)

- The optimization of storage space, for making the best use of all available space (crucial in a boat!)

- The ease and repeatability of assembly, to ensure consistent quality at the best price

- Price, by optimizing the nesting of parts within available timber sizes.

Beyond these intuitive criteria, other, less obvious, parameters are taken into account in industrial sites:

- The reduction of cutting lengths, for digitally controlled CNC machines

- The rigidity and solidity of the module outside the boat, so that it can be handled during construction

- The use of existing tooling in our wood shops (router bit diameters, bevel angles, etc.)

- Ease of access behind the modules, for quality control at the end of production.

In short, there are many criteria that go into a boat module. It’s more than just a piece of furniture!

And to all this, on the Excess 14, we added a major design criterion: the module's weight.

We challenged our designers to create a reduction of 20 to 25% in weight compared to a traditional unit, and this of course without compromising the other criteria…

Ultimately, the Excess 14 seems to have won the bet! The first modules are now under construction, and they really are lighter, still as rigid, and we can clearly see the emphasis put on weight optimization.

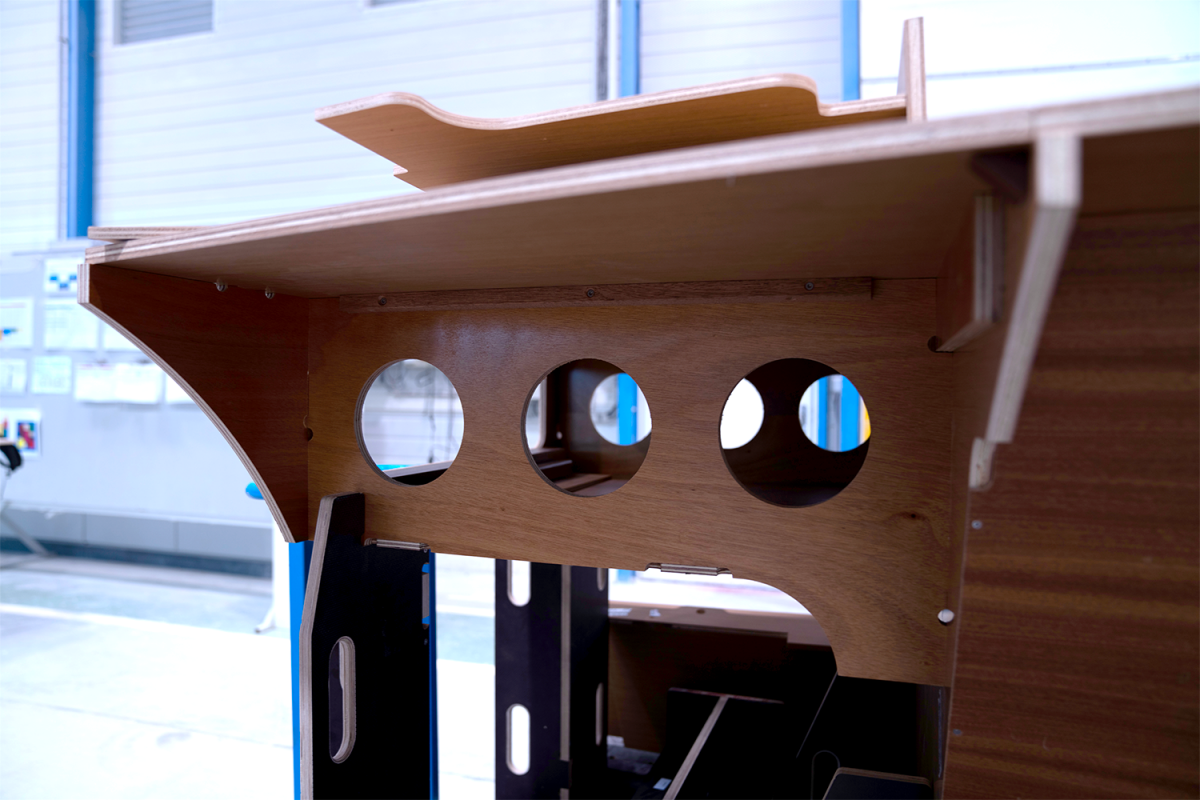

For example, for the ‘dressing room’ in the owner's hull, we can see both the respect of the design (perfectly in line with the Excess range), and when we look ‘behind the curtain’, we can visualize all the weight optimization on each piece of wood, the cut-outs in the non-structural sections, the ‘precise’ cutting of the visible panels, the use of only one part to perform two functions, etc.

Another example, one that’s even more striking, is the housing for the electrical panels. For this technical module, no smart look was involved, meaning the creator was able to push the design optimization even further.

It is still too early to fully assess all this work that’s gone into the Excess 14. Economically, cutting holes in a panel has a cost, but on the other hand, managing to do without a piece of wood means a gain.

As for the gain in sensations, the verdict will be apparent on launch day. And we can't wait to share it with you!

that is still looking good. Well done

kind regards

Rainer